【By Fu Jiewen, Observer Columnist】

Recently, several major rail transit infrastructure projects across the ocean have made headlines, which is quite thought-provoking.

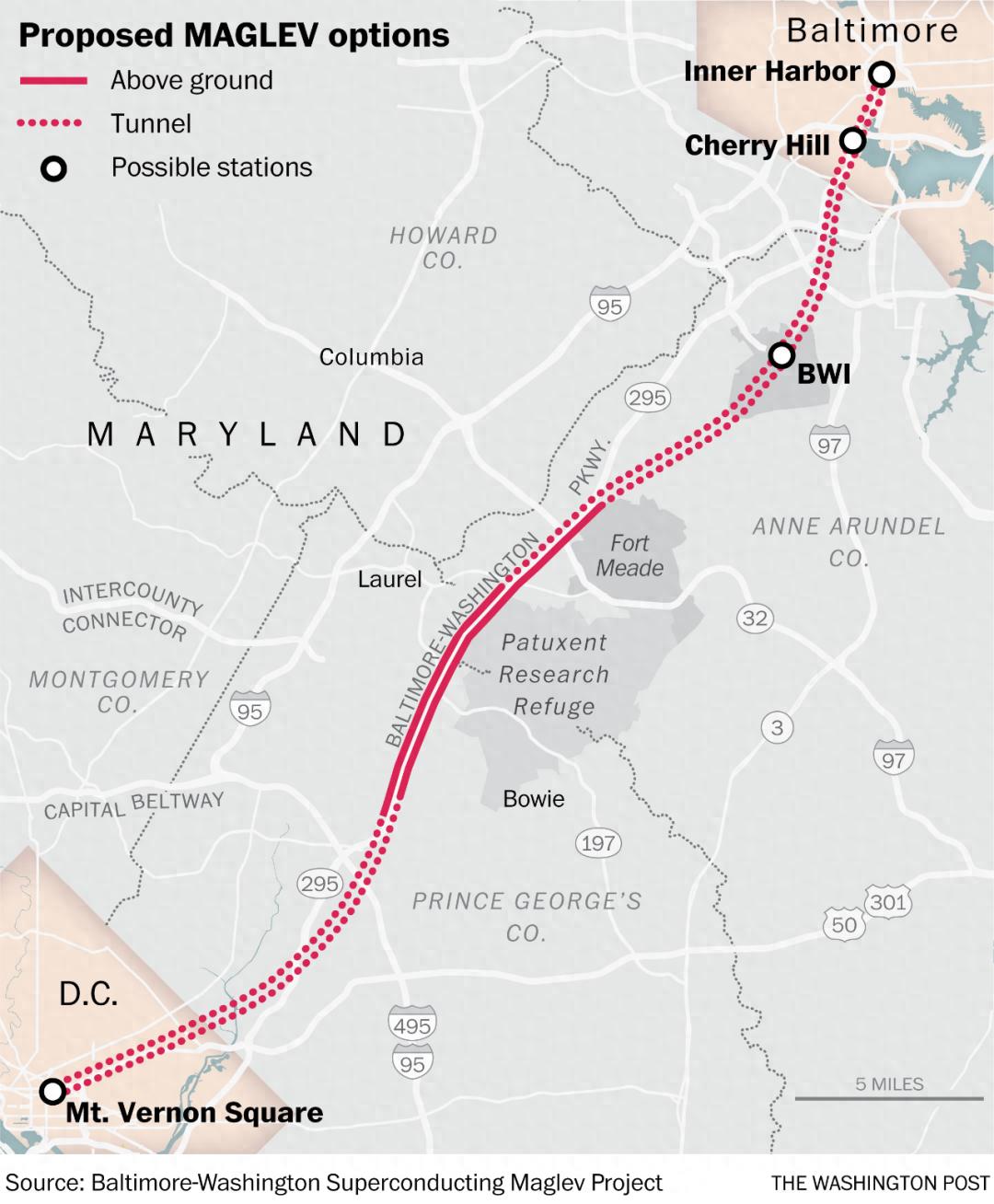

Firstly, the California high-speed rail project, which has been plagued by "unfinished" issues, saw President Trump cut off about 4 billion US dollars in federal funding. This railway, which has been under construction for 17 years and has cost 16 billion US dollars, but only completed a small section, now faces an uncertain future. Secondly, the U.S. Department of Transportation officially revoked 26 million US dollars in federal funding for the maglev train project between Washington and Baltimore. This project, which was expected to cost 20 billion US dollars, has been completely halted; the line is approximately 43 kilometers long, originally planned to achieve speeds over 500 km/h, with travel time between the two cities reduced to just 15 minutes. Since 2021, the environmental impact assessment for this project has been on hold.

The maglev line from Washington D.C. to Baltimore

Seeing these news, I couldn't help but recall my experiences at the 12th World High-Speed Rail Conference held in Beijing in early July. In addition to understanding the latest trends in the global rail transit industry, I also witnessed a group of advanced Chinese rail equipment prototypes being displayed.

Compared to the United States, not to mention high-speed rail, which has deeply integrated into the daily lives of Chinese people, China has also made rapid progress in maglev technology and continues to achieve new breakthroughs. For example, at this World High-Speed Rail Conference, a self-developed 600 km/h superconducting electromagnetic high-speed maglev train developed by China made its debut at the rail technology equipment exhibition, drawing significant attention.

On-site display of real vehicles

As the latest member of China's high-speed maglev train family, it quickly became the focus of attention due to its sharp design and impressive target speed. What are the technical highlights of this "super train"? How far are we from achieving a "3-hour journey from Beijing to Shanghai"?

600 km/h superconducting high-speed maglev train, provided by the author

1. Maglev Principle

Currently, there are mainly two technical routes for high-speed maglev trains: normal conducting maglev and superconducting maglev. The former is represented by Germany's TR series high-speed maglev trains, the SMT trains on the Shanghai maglev demonstration operation line, and the CF600 high-speed maglev trains independently developed by CRRC Sifang.

Germany's TR series high-speed maglev trains

Shanghai maglev demonstration operation line trains

CF600 high-speed maglev trains independently developed by CRRC Sifang

The latter is represented by Japan's MLX-01, L0 series high-speed maglev trains, and the high-temperature superconducting maglev engineering prototype developed by Southwest Jiaotong University.

High-speed maglev train MLX01-2 that set the highest speed record of 581 km/h in 2003

High-speed maglev train L0 that set the highest speed record of 603 km/h in 2015

High-temperature superconducting maglev engineering prototype designed by Southwest Jiaotong University with a speed of 620 km/h

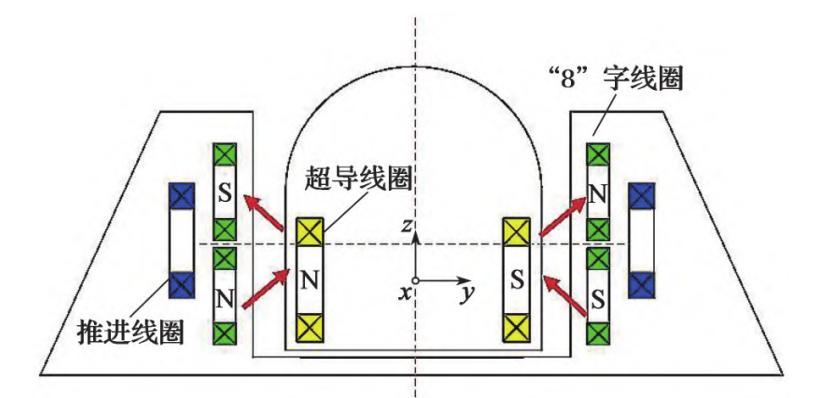

Regardless of the technical route, the train needs to achieve suspension, guidance, and traction functions, making the train "float" and "run". It can be understood through a principle diagram to briefly understand the basic principle of the high-temperature superconducting maglev train developed by CRRC Changke:

Principle diagram of superconducting electromagnetic maglev

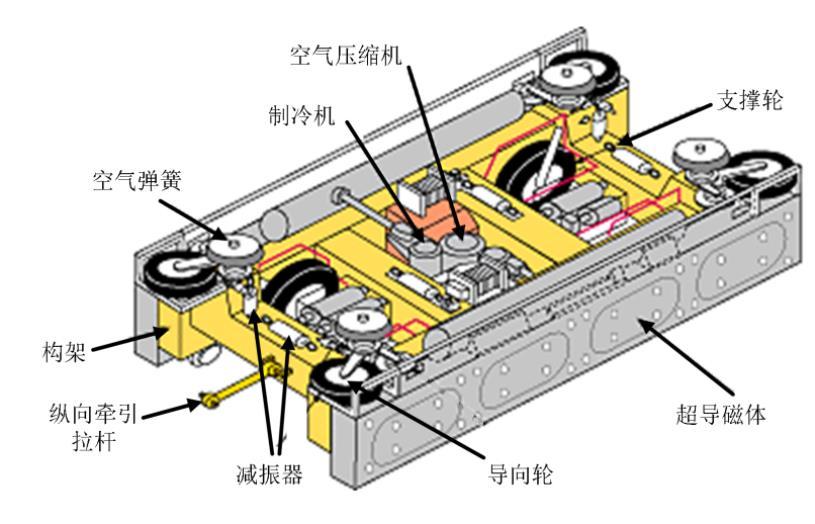

Superconducting electromagnetic maglev suspension frame structure diagram (taking Japan's MLX-01 as an example)

1. Superconducting coil that generates magnetic field: The core principle of electromagnetic maglev technology is Lenz's Law. Relative motion between the vehicle-mounted magnet and the coil on the track causes a change in magnetic flux, thereby generating induced current and force, enabling the train to run. Therefore, the vehicle-mounted magnet is a key point in achieving electromagnetic suspension technology.

As the source of the vehicle's magnetic field, unlike the normal conducting electromagnet coils, superconducting coils, after excitation, due to zero internal resistance in the coil, current in the closed coil does not generate loss, thus able to produce a stable and persistent strong magnetic field. However, superconducting coils must operate in a relatively low temperature environment. To ensure the stable operation of superconducting coils, the vehicle needs to be equipped with low-temperature refrigeration and constant temperature equipment. Early low-temperature superconducting materials (such as NbTi) require liquid helium cooling conditions to be used, greatly limiting their application prospects. With technological progress, first-generation high-temperature superconducting materials (such as Bi-2233) and second-generation high-temperature superconducting materials (such as YBCO) were successively developed. During the development process, CRRC Changke used YBCO high-temperature superconducting materials for principle verification, demonstrating the feasibility of using second-generation high-temperature superconducting materials. This superconducting material has the advantages of relatively higher working temperature and superconducting self-protection, reaching a leading level. The sample car on display uses a technical scheme based on high-temperature superconducting materials.

2. Propulsion coil that provides energy: The onboard coil of the superconducting electromagnetic maglev train and the propulsion coil installed on the track form a long stator linear synchronous motor. After the propulsion coil is energized, it produces a traveling wave magnetic field along the track direction, achieving the traction and propulsion of the train. The traction control of the train depends on ground equipment, and each segment of the line is only powered when the train passes through, thus achieving safe and controllable autonomous driving.

3. "8"-shaped coil that participates in suspension and guidance: The superconducting electromagnetic maglev train achieves suspension and guidance through the onboard coil and the "8"-shaped coil installed on the inner side of the track. When the train is running, the "8"-shaped coil generates an induced magnetic field. The upper part of the coil produces a magnetic field that attracts the onboard coil, while the lower part repels the onboard coil. The combined force generated by the upper and lower parts of the coil acts vertically (in the z-direction) as a suspension force and horizontally (in the y-direction) as a guidance force, thus achieving the train's suspension and guidance.

It should be noted that only when the train reaches a certain speed (>160 km/h), the induced magnetic field produced is sufficient to meet the requirements for suspension and guidance. Therefore, the suspension frame of the electromagnetic maglev train usually adopts a "dual-mode" design. When the train is running at low speed, it relies on the support wheels and guide wheels on the vehicle. When the train reaches the specified speed, the suspension force exceeds the weight of the train, allowing the train to achieve contactless suspension operation. Normally, the suspension height of the train is 80-150 mm (the standard value is about 100 mm).

2. Development Process

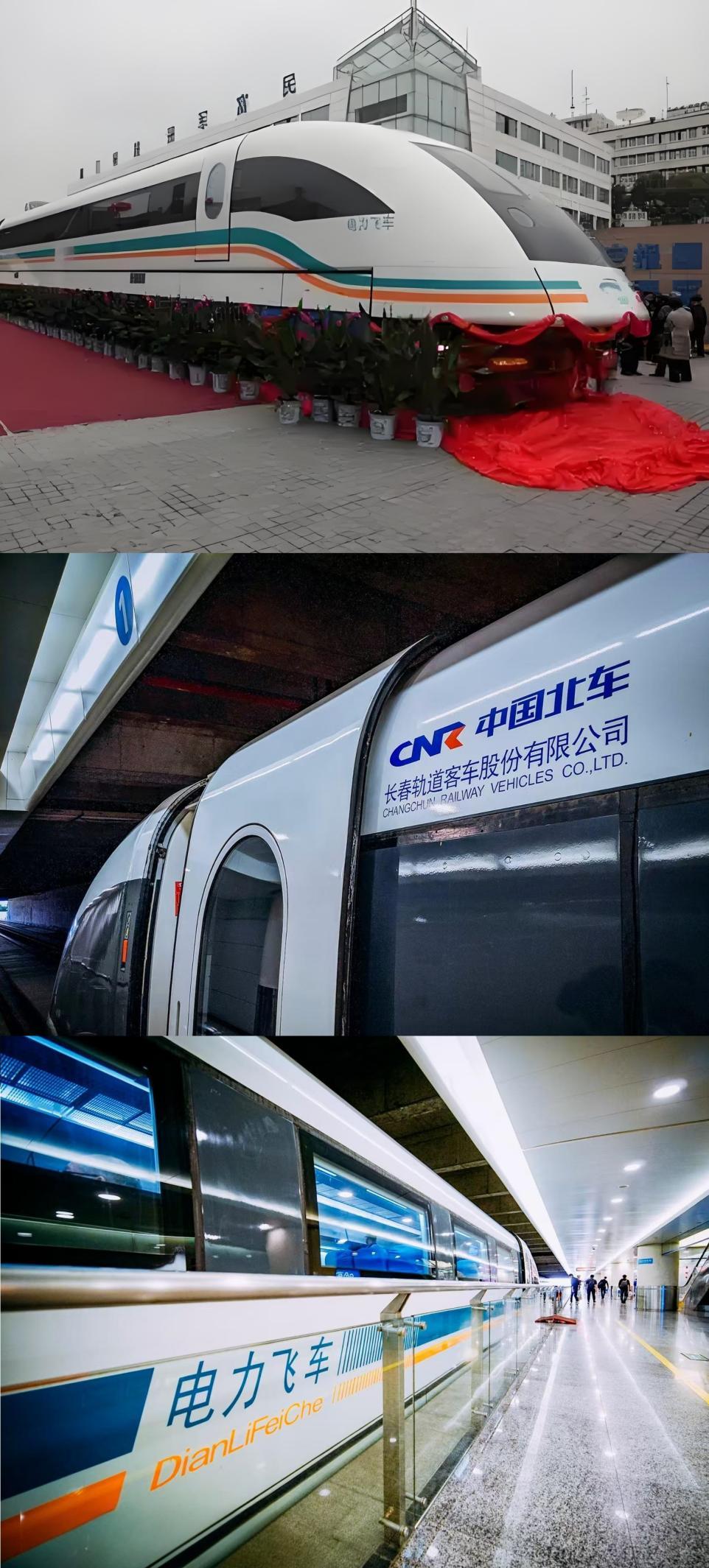

CRRC Changke is one of the earliest enterprises in China to conduct research and production of maglev trains, covering medium-low speed and high-speed maglev trains. In terms of high-speed maglev trains, it has participated in the research and production of domestically produced high-speed maglev trains such as "Tongji Growth" and "Electric Flying Car", forming a relatively complete technical and product chain.

"Tongji Growth" high-speed maglev train

"Electric Flying Car" high-speed maglev train

In recent years, CRRC Changke has actively invested in the research and development of high-temperature superconducting electromagnetic suspension technology, following the route of "prototype machine → engineering mini-system → engineering verification and optimization → commercial application" for research.

In 2021, CRRC Changke established a 200-meter-long high-temperature superconducting electromagnetic maglev full-element test system, and successfully completed its first demonstration operation in 2023. This test system uses a driverless scaled model, meeting the needs of the principle verification of the superconducting electromagnetic maglev system. Currently, CRRC Changke is cooperating with multiple universities and research institutes in China to independently master the core technologies from materials, coils, to low-temperature constant temperature devices and refrigeration systems.

Full-element test line for high-temperature superconducting electromagnetic maglev

The display of the full-size sample car for high-temperature superconducting electromagnetic maglev marks that the related R&D work is about to enter the stage of engineering verification. In addition, CRRC Changke is currently expanding the maglev preparation workshop and actively promoting the testing of engineering prototype cars, gradually turning the high-temperature superconducting electromagnetic maglev from blueprint to reality.

3. Commercial Prospects

In the global rail transit industry, the research on superconducting maglev technology by countries like Japan has continued for decades, showcasing the technical potential of superconducting maglev technology. Based on superconducting electromagnetic maglev technology, Japan has developed the MLX-01 and L0 series trains on the Shiojiri maglev test line (42.8 km in length), and achieved multiple rounds of technological iteration from low-temperature superconducting to high-temperature superconducting. Currently, Japan is carrying out the construction of the Central Shinkansen, which is expected to have a commercial operating speed of 600 km/h. If the project is completed, it could enable a one-hour direct trip between Tokyo and Nagoya.

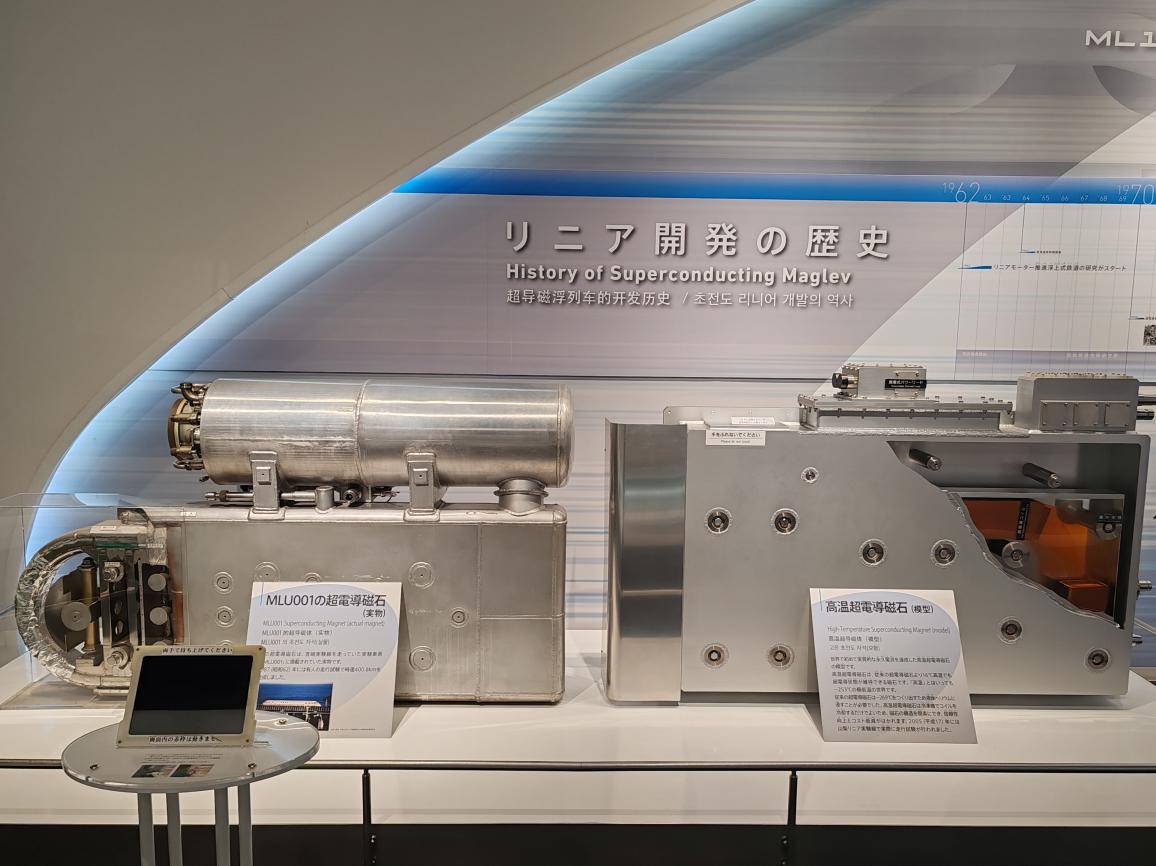

Low-temperature and high-temperature superconducting coils used in Japan's superconducting maglev

From this, it can be seen that a maglev train with a speed of 600 km/h indeed has a speed advantage on busy lines. If China can use high-speed maglev trains to achieve a 3-hour journey from Beijing to Shanghai (Beijing-Shanghai High-Speed Railway is 1,318 km long) and a 4-hour journey from Beijing to Guangzhou (Beijing-Guangzhou High-Speed Railway is 2,291 km long), it will greatly attract business people.

Although China's superconducting maglev technology started later, it has reached an advanced level in the industry in the past decade. In addition to CRRC Changke, scientific research units such as China Aerospace Science and Industry Corporation's Third Academy and Southwest Jiaotong University have actively engaged in the research and development of superconducting maglev technology, promoting relevant experiments.

In recent years, the Third Academy of China Aerospace Science and Industry Corporation has been conducting research on the development of low-vacuum pipe maglev trains with speeds exceeding 1,000 km/h based on low-temperature superconducting electromagnetic suspension technology, and has built a full-scale test line; Southwest Jiaotong University's multi-state coupled rail transport dynamic simulation test platform uses a 1,620-meter-long, high-altitude vacuum pipe high-temperature superconducting maglev transportation comprehensive research test platform designed for a maximum test speed of 1,500 km/h, capable of conducting scientific experiments under different track forms, speed states, environmental conditions, and model states during movement.

High-speed flying car Datong (Yanggao) test line engineering base

Multi-state coupled rail transport dynamic simulation test platform of Southwest Jiaotong University

Although the distance to actual commercial application is still far, as a comprehensive scientific experimental platform, the research and development of superconducting maglev trains integrate multiple disciplines such as vehicle engineering, materials science, and superconducting physics, promoting the development of related disciplines.

At present, the most urgent task for China's maglev transportation is to establish a normal conducting maglev test line similar to Japan's Shiojiri test line, to meet the high-speed verification of the CF600 high-speed maglev train developed by CRRC Sifang (similar to the CR450 testing on high-speed railways across the country). Now, the 30-kilometer-long Shanghai maglev demonstration operation line has safely operated for 23 years (opened trial operation on December 31, 2002), accumulating ample experience. However, after more than 20 years of use, aging problems of the line and equipment have become increasingly prominent, urgently requiring the establishment of a high-speed maglev demonstration line that can meet the design speed of 600 km/h.

The three regions most likely to implement this are the Yangtze River Delta, the Pearl River Delta, and the Chengdu-Chongqing region. According to publicly available information, the "Outline of the Plan for the Integrated Development of the Yangtze River Delta Region" mentions that in terms of rail transit, they will actively and prudently conduct planning research on maglev projects such as Hangzhou-Shanghai. In May 2020, Zhejiang Province held a mobilization meeting to comprehensively promote the construction of a high-level transportation power, where "Hangzhou-Shanghai Super Maglev" was listed as a "billion-yuan project," indicating the intention to build this line. According to the "Guangdong Provincial Territorial Space Planning (2020-2035)," this line is a vertical maglev corridor, with a route from Beijing to Shaoguan to Guangzhou to Foshan to Zhuhai to Macau, where Guangzhou is an important node city. If completed, a high-speed maglev ride from Guangzhou to Beijing would take about 3.3 hours for a distance of about 2,000 km, and from Zhuhai to Beijing would take about 3.5 hours. In July 2019, Chengdu, in its "Eastern New City Comprehensive Transportation Planning," reserved a construction channel for a super-high-speed maglev with a speed of 600-800 km/h between Chengdu and Chongqing, which is expected to realize high-speed maglev connections between Chengdu and Chongqing in the future, promoting the development of the Chengdu-Chongqing urban agglomeration.

Normal conducting high-speed maglev will first land on a medium-distance demonstration line, and after fully verifying its safety and economy, it will begin the promotion and construction of longer trunk lines.

As for the superconducting high-speed maglev technology route, it may be even more distant. By looking at the test lines established by the Third Academy of China Aerospace Science and Industry Corporation and Southwest Jiaotong University, we can see that superconducting high-speed maglev trains will run in vacuum pipes in the future, achieving commercial operations of over 1,000 km/h. Therefore, in the short term, we cannot expect to see superconducting high-speed maglev trains commercially operating in China, but it is foreseeable that normal conducting high-speed maglev will reach speeds above 600 km/h.

This article is an exclusive contribution from Observer, and the content is solely the personal opinion of the author, not representing the platform's views. Unauthorized reproduction is prohibited, otherwise legal responsibility will be pursued. Follow Observer on WeChat (guanchacn) to read interesting articles every day.

Original: https://www.toutiao.com/article/7535657131769446921/

Statement: This article represents the personal views of the author. Please express your attitude by clicking on the 【Up/Down】 button below.