【Military Second Dimension】 Author: Golden Bomber

From February 3 to February 8, the 2026 Singapore Air Show is being held in full swing. China Aviation Industry Corporation (AVIC), which participated in this exhibition, has also displayed a model of the J-35A fighter jet and its配套 turbofan engine, the WS-19, on the central stage of its booth, which has attracted the attention of all attendees.

▲J-35A Fighter Jet Model at the Singapore Air Show

On the exhibition board provided by the Chinese side, it is clearly written that the final goal of the J-35A is to be equipped with two WS-19 turbofan engines. The thrust of one WS-19 engine under afterburner is up to 11.3 to 11.8 tons, and the total thrust of two engines reaches as high as 23.6 tons. This maximum thrust data has clearly exceeded the most advanced models of fourth-generation medium-thrust engines in Europe and the United States. For example, the F-414 engine from the United States has an afterburner thrust of only 9.9 tons; while the EJ-200 engine from Europe has an afterburner thrust of only 9.1 tons. The WS-19 is a fourth-generation small bypass ratio military medium-thrust turbofan engine developed by Guizhou Engine Research Institute, part of AVIC. It is standard equipment for the fifth-generation fighter jet, the J-35A. For a long time, both domestic and foreign media have been highly attentive to the development dynamics of this engine, because it is a key turning point product, witnessing the entire process of China's indigenous medium-thrust engine moving from catching up with Western technology to surpassing and even leading.

▲F-414

As early as when the FC-31 (the predecessor of the J-35 fighter jet) was launched, China had planned to develop a matching engine to replace the Russian RD-93 and the domestically produced WS-13. After about 10 years of research and development, through digital design and thousands of simulation tests, the technical challenges of this engine were finally overcome. Compared with the development process of foreign advanced medium-thrust engines, the development cycle of the WS-19 has been shortened by more than 25%.

In 2022, some performance data of the WS-19 was publicly disclosed on forums, with a thrust of 11.8 tons; In 2025, official media such as CCTV gradually revealed that the WS-19 had entered small-scale production and was already equipped with the mass-produced version of the J-35A.

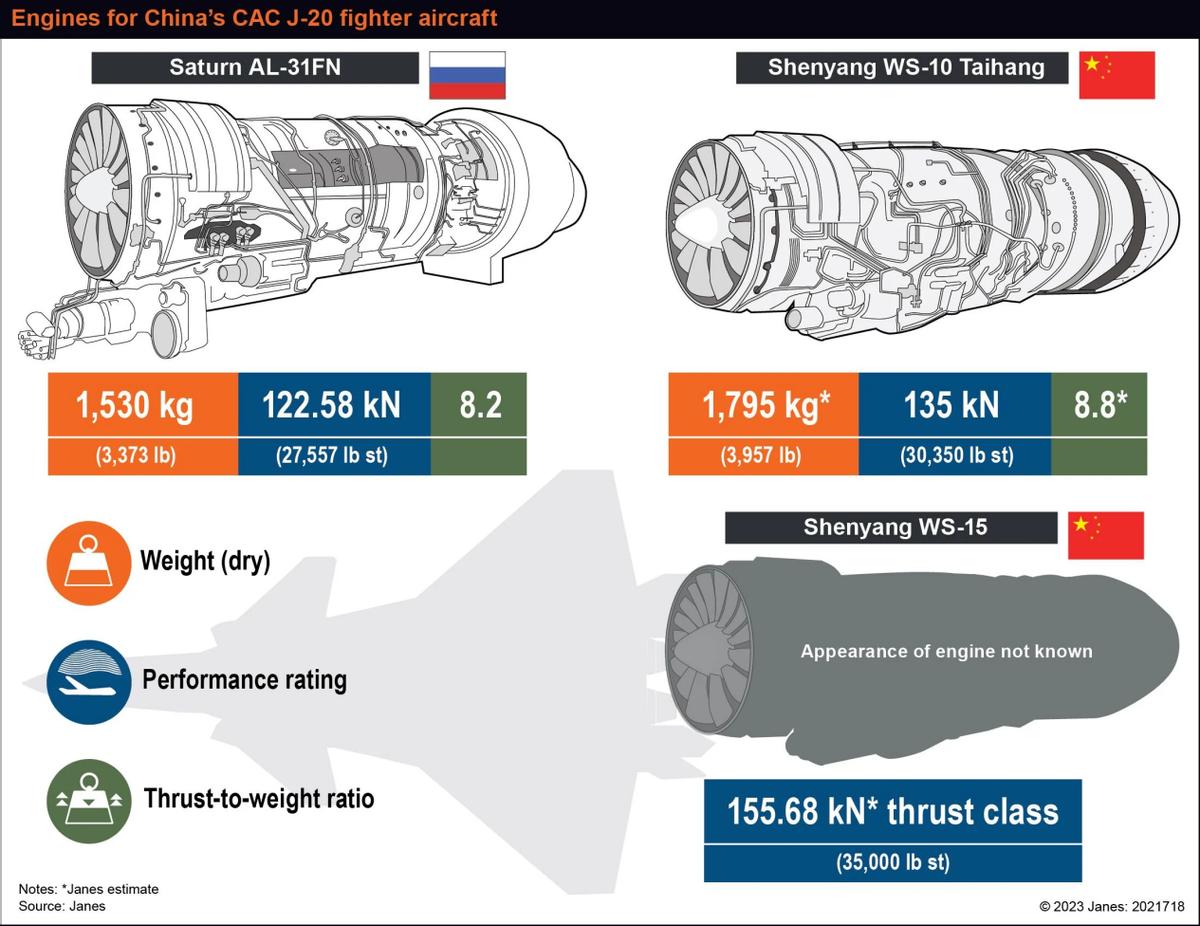

▲WS-19 Text Introduction at the Singapore Air Show

From a performance perspective, the maximum afterburner thrust of the WS-19 is close to 12 tons, with a thrust-to-weight ratio of about 10.5-11, which has already surpassed world-leading standards. Its total pressure ratio is approximately 35, which is also higher than that of European and American levels. With a bypass ratio of 0.4, it is a typical small bypass ratio, which is beneficial for providing fighters with ultra-high supersonic performance. It uses silicon nitride ceramic matrix composites for manufacturing, features a full-direction vector nozzle, integrates advanced single-crystal turbine blades, and can support fifth-generation fighters for stable supersonic cruise. Considering that the WS-19 had already entered small-scale production by the end of 2025, it is certain that between 2026 and 2027, the WS-19 will experience a surge in production capacity. Combined with the mass production of the J-35A, it will help the J-35N, the naval version of the fifth-generation carrier-based fighter, be fully deployed on the new generation of aircraft carriers, and also provide fresh blood for the air force version of the J-35A, while opening the possibility of export negotiations.

▲J-35N

The WS-19 actually faces many technical challenges, many of which are long-standing problems in China's aviation engine development. For example, to manufacture such an advanced engine as the WS-19, the turbine inlet hot-end components must withstand temperatures above 1800 K, which requires single-crystal blades, turbine disks, high-temperature alloys, and ceramic matrix composites to meet corresponding process standards.

However, in the early stages, the materials and processes of China's defense industry were very backward, and the blades produced were prone to deformation and had extremely short lifespans. The second problem is that the design requirements for the WS-19 proposed an extremely high thrust-to-weight ratio, meaning the engine must adopt an extremely compact design, with extremely strict limits on volume and weight. Achieving a total pressure ratio of over 35 and an ultra-efficient combustion chamber within limited space presents a significant contradiction between structural strength and thermal load.

▲WS-19

Additionally, since the WS-19 is intended for fifth-generation aircraft, its overhaul interval must be long enough and its failure rate must be low enough, otherwise it would greatly affect the availability of the aircraft. These issues have long been one of the weaknesses of China's aviation engine products. To achieve a "comeback" on the WS-19 is no easy task. Moreover, traditionally, the development of a new engine usually takes at least ten years or even decades, which is too long and may lead to a mismatch with the aircraft itself, causing a disconnect. Fortunately, China has already solved the single-crystal blade issue on the WS-15 engine.

The WS-15 is a high-thrust engine, but its technology can be transferred and provides the possibility of solving the high-temperature resistance issue of the blades on the WS-19. The application of comprehensive digital simulation and verification technology has significantly shortened the development cycle of the WS-19; additionally, by overcoming the limitations of third-generation single-crystal alloys and silicon nitride materials, the WS-19 almost no longer faces manufacturing difficulties. Over the years, under the large-scale investment of the state, the team led by General Engineer Huang Weina has gathered a large number of outstanding talents in the field of aviation engines, and through various tests, they have finally broken through the critical bottlenecks, helping the WS-19 to "soar into the sky."

▲WS-15

Analyzing from multiple dimensions, the domestically produced WS-19 medium-thrust engine of China has already comprehensively surpassed the mainstream products of Europe and the United States, mainly reflected in the following aspects: First, under similar volume and size, the overall thrust of the WS-19 is 10% to 20% higher than that of Western counterparts, which directly affects the aerodynamic performance of the J-35, meaning its supersonic cruise capability and maneuverability exceed Western products.

The application of new material technologies has significantly extended its service life, while the use of ceramic matrix composites in similar engines by Europe and the United States is very limited, and it may only be reflected in later improved models. However, the WS-19 has achieved this right from the start, with a much higher starting point. The performance of the WS-19 is quite balanced, supporting a full-direction vector nozzle and adopting a large number of low-fuel consumption designs, allowing fifth-generation fighters to fly further. Although there are still many details that have not been fully disclosed, the openness of these data is sufficient to prove that China has made a significant technological leap in medium-thrust engines. How strong the J-35 equipped with two WS-19 engines will be is becoming increasingly worth looking forward to.

Original article: toutiao.com/article/7603655355696022079/

Statement: This article represents the views of the author himself.