"More than a decade ago, he tried to manufacture smartphones in the United States to capture a larger share of the smartphone market dominated by Apple and Samsung. Now, he wants to offer some advice to companies that are trying to do the same," wrote CNN in a recent report.

Dennis Woodside, former CEO of Motorola and current CEO of Freshworks, told the American media: "Some customers said, 'Hey, if you produce your products in the United States, I'm more likely to consider it.'"

But these efforts did not last long. The following year, Motorola closed its factory in Texas and abandoned domestic assembly for the Moto X, which was the flagship phone at the time, intended to compete with the latest iPhones and Samsung Galaxy devices.

Image source: Amazon screenshot

The Wall Street Journal reported on November 11, 2013, that due to poor sales, Motorola reduced the U.S. price of its high-end Moto X (which came with a two-year carrier contract) from $200 (about 1,436.5 RMB) to $100 (about 718.26 RMB).

According to research firm Strategy Analytics, the Moto X sold approximately 500,000 units in the third quarter after its August launch. In comparison, Samsung stated that its Galaxy S4 sold over 10 million units within a month of its April release.

CNN's analysis noted that Woodside's experience highlights why many tech products, such as smartphones, are mainly assembled in Asia and South America rather than the United States. Proximity to key suppliers and lower labor costs are only part of the reason; the real challenge of moving smartphone production back to the U.S. lies in the necessary skill gaps and the difficulty of filling factory jobs.

Recently, the problem that Motorola faced over a decade ago has resurfaced, as President Donald Trump is pressuring Apple and Samsung to produce mobile devices in the United States or face tariffs. China is the assembly location for many electronic products. India is currently the largest smartphone exporter to the United States, and new tax rates will take effect on August 7, subjecting India to a 25% tariff.

Woodside took charge of Motorola under Google in May 2012 until it was acquired by Lenovo in 2014. He offered advice to any company attempting to produce smartphones in the United States: don't underestimate the difficulty of finding and retaining skilled workers.

In 2013, the tech company, then owned by Google, made a bold bet by deciding to produce its Moto X smartphones in Fort Worth, Texas. Through Motorola's website, consumers could customize certain appearance details of the phone, such as the color of buttons and the back panel - one of the main selling points of the device.

Woodside said, "To do this, you have to be closer to the consumer in production." Although Motorola assembled the Moto X sold in the United States in Texas, components such as batteries, screens, and motherboards came from Asian suppliers.

One of the biggest challenges he faced was training and retaining employees. Employees had many other options, such as retail or restaurant service, making it very difficult to attract and retain them. At the same time, the nature of the work made things even harder.

Woodside said, "This phone may have hundreds of parts, and they are all very small." He compared it to "a set of ultra-small LEGO blocks."

"What we didn't realize was that most people in the U.S. are not used to this kind of work," he said, "we had to train people for this specific job."

Woodside's experience touches on a reality well known to those who focus on trade and manufacturing: the U.S. is facing a shortage of skills and demand, which makes it difficult to fill factory jobs and achieve domestic production of tech products like smartphones.

According to data from the U.S. Bureau of Labor Statistics, the U.S. manufacturing sector lost about 11,000 jobs between June and July. This number is lower than the approximately 15,000 manufacturing jobs lost between May and June, but in terms of the number of layoffs, manufacturing remained one of the hardest-hit industries in the past month.

Although Trump's tariff policies pose challenges for creating new factory jobs, there is evidence that factories have struggled to find suitable talent before, and Americans may simply not want to work in factories.

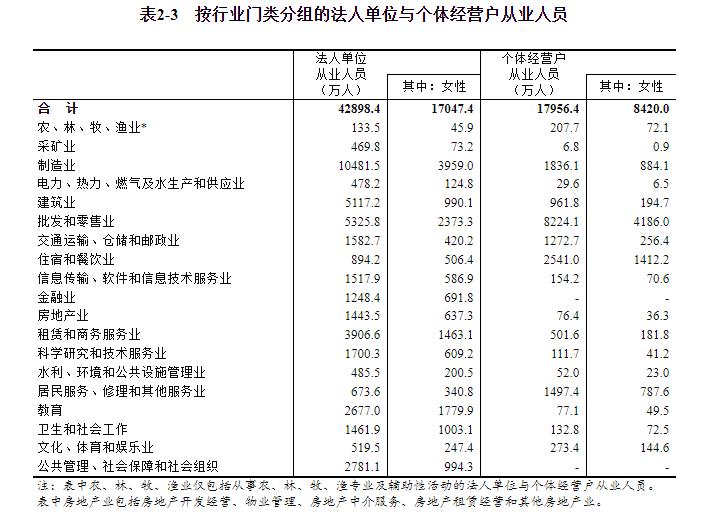

China's situation is different, where the smartphone assembly labor market is abundant, and the manufacturing industry is booming. According to the fifth national economic census data released in December 2024, in 2023, the number of people employed in China's manufacturing industry was about 123 million, the highest among all industries.

Report No. 2 of the Fifth National Economic Census Released on December 26, 2024 - Basic Information of Units Source: National Bureau of Statistics

This June, the Trump Organization officially launched its own brand "T1 Mobile" and its first smartphone "T1", trying to highlight "Made in America" and since May, President Trump has repeatedly called on Apple CEO Cook to keep iPhone production in the United States.

However, shortly after, the Trump Organization quietly removed the statement that its launched smartphone would be "made in America," changing its website content to vague and broad statements, saying that the $499 (about 3,577 RMB) smartphone would be "designed based on American values" and "born in the United States."

The Financial Times reported in June that so far, the U.S. has not produced a mainstream smartphone. A truly "American-made" phone requires "all or almost all" components to be made in the U.S.

Given China's significant role in the global smartphone supply chain, experts have raised doubts about whether using U.S.-made components can create more competitive devices.

A report published by the Canadian Asia-Pacific Foundation on March 14, 2024, stated that China's capacity covers almost the entire smartphone supply chain. China has a skilled workforce, a strong domestic supplier network, and an increasingly digitalized industrial infrastructure, allowing annual cost savings of 20% to 50% compared to regional competitors.

Apple CEO Tim Cook described in a speech at a Fortune magazine event in 2017 the reasons why Chinese labor became ideal for smartphone manufacturing, stating that China combines "craftsman" skills, "precision robotics technology," and the "world of computer science."

This article is an exclusive contribution from Observer, and unauthorized reproduction is prohibited.

Original: https://www.toutiao.com/article/7537236937615131190/

Statement: The article represents the views of the author. Please express your opinion by clicking the [Up/Down] button below.