Who could have thought that the last veil of shame for the United States in the field of aviation engines has also been removed. According to information from the Chinese Academy of Sciences, China's variable cycle engine has completed full-scale ground testing and full-scale high-altitude testing, far surpassing the United States.

It should be noted that China's variable cycle engine adopts a triple duct ratio variable cycle, which is considered the top technology of the fifth generation of variable cycle engines. This means that the heart of China's sixth-generation fighter has undergone a complete transformation.

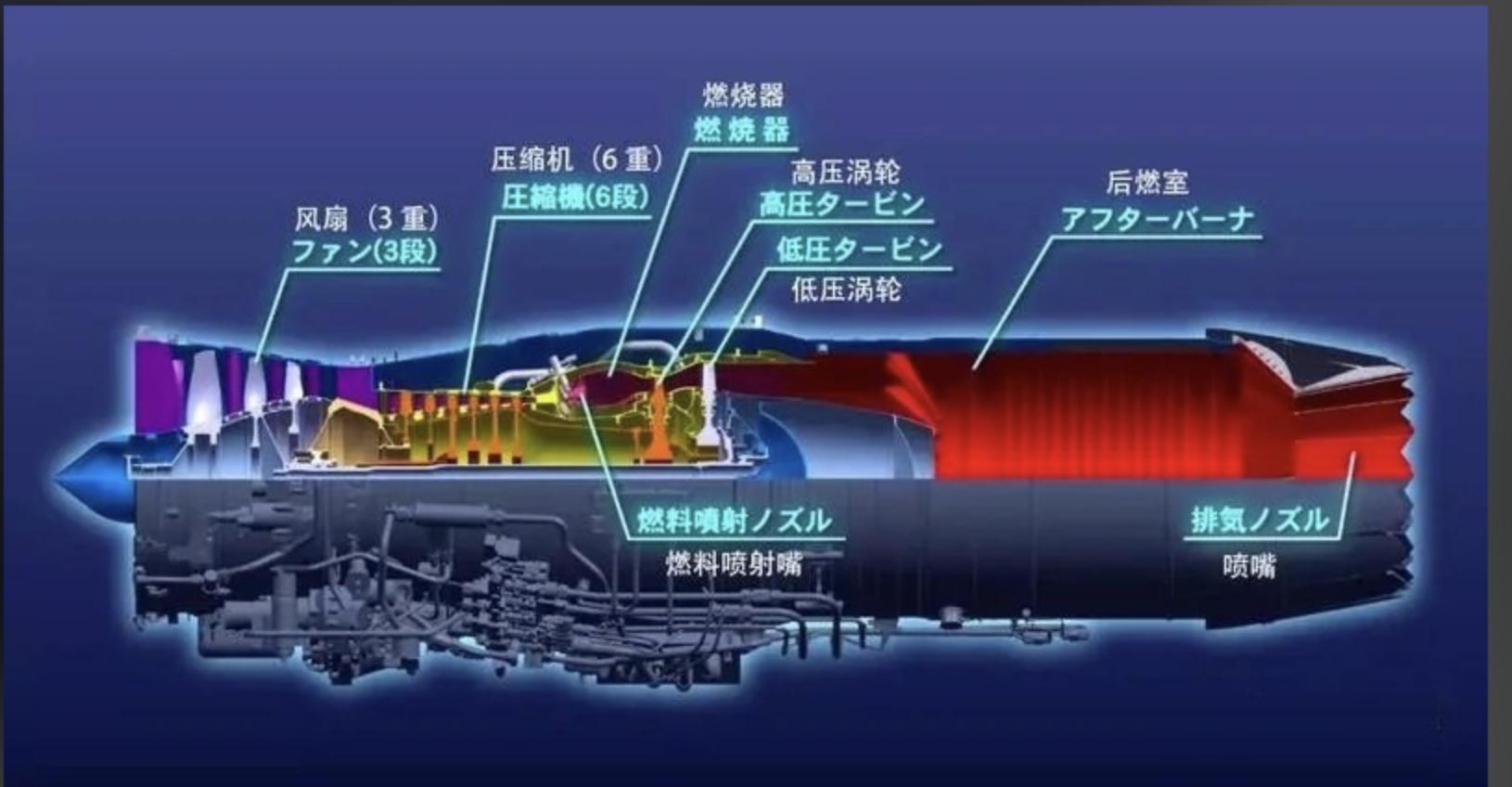

In a conventional turbofan engine, the internal and external duct structures are fixed, so the bypass ratio cannot be changed. A variable cycle engine changes the bypass ratio, simultaneously combining the advantages of large and small bypass ratios, meeting the needs of different combat environments. The principle lies in its multiple ducts, which can change the airflow entering the internal and external ducts through the opening and closing of valves on the ducts, enabling flexible switching to adapt to different combat backgrounds. By adjusting the bypass ratio, range and speed are no longer an "unattainable fish and bear's paw," and the aircraft can gain performance advantages at both high and low speeds.

For example, during takeoff and subsonic flight, the bypass ratio of the engine increases, working in a turbofan mode to reduce fuel consumption and noise. During climb, acceleration, and supersonic flight, the bypass ratio decreases, operating with performance close to that of a turbojet engine, increasing thrust.

According to public data, adaptive variable cycle engines can increase the loiter time of combat aircraft by 50% with the same amount of fuel, increase the maximum range by 33%, reduce fuel consumption rate by 25%, and achieve a fuel thermal absorption rate of 60%.

This concept was proposed by the United States as early as the 1960s. Currently, two main U.S. engine manufacturers - General Electric's XA102 and Pratt & Whitney's XA103 projects - are still struggling to advance this technology. However, realizing this concept faces significant challenges. Variable cycle engines rely on a large number of adjustable geometric structures, such as adjustable duct guide vanes and valves. These components are prone to flow distortion and mechanical failures when working under extreme conditions of high temperature, high pressure, and high rotational speed, directly threatening the stability and reliability of the engine.

At the same time, its control system is extremely complex. The engine needs to coordinate numerous movable parts within milliseconds, with a large number of control variables and complex control rules, far exceeding traditional engines. This requires the control system to be able to respond accurately in real-time to changes in various flight conditions.

Technical difficulties directly lead to project delays. The U.S. Air Force has confirmed that the development of variable cycle engines will be delayed by at least two years, and it is unlikely to be completed before fiscal year 2030. This means that even whether the sixth-generation fighter currently under development can use it is questionable.

High R&D costs are another key factor limiting progress. It has been reported that both General Electric and Pratt & Whitney have continuously requested increased funding from the Pentagon due to financial pressures. This continuous high investment contrasts sharply with the slow progress, making the practical application of variable cycle engines still a distant prospect.

However, China is different. China had already completed the first full-scale verification of the unique key technologies of variable cycle engines in 2018, established a key technology system for adaptive engines, and achieved a major breakthrough in independently developed aviation engine technology.

Starting from the Turbofan 10, China gradually copied the U.S. model of aviation engine development, following the "key core components - core engine - technical verification engine - engineering verification engine - prototype engine" development model and the "service one generation, develop one generation, pre-research one generation, explore one generation" development model. The Turbofan 15 fully replicated the U.S. engine development model, completing the entire development process.

Therefore, according to China's publicly available timeline, China can achieve mass production of variable cycle engines around 2028. Taking this publicly disclosed variable cycle engine as an example, according to the data, if China's sixth-generation fighter uses three-variable cycle engines and integrates hypersonic missiles internally, it would truly establish a containment zone within the third island chain.

When many people still hold the old view that China's engine technology is 30 years behind the United States, China has already achieved a leapfrog development. In these 30 years, the United States not only stagnated in the field of variable cycle engines, but also failed to produce any engine surpassing the F119. In other words, the United States has been stagnant in small bypass ratio high-thrust engines for 30 years. While China's Turbofan 15 surpassed the F119, achieving a thrust of 18.5 tons, it is currently the most advanced small bypass ratio high-thrust engine in the world. Worse still, the U.S. military's F119 engine has been exposed to fraud.

Therefore, the claim that China's aviation engine technology is 30 years behind the United States is incorrect. In fact, when China has achieved comprehensive success in detonation engines, scramjet engines, and variable cycle engines, it means that China has started to overtake in the field of engines.

Another fact is that the development of the U.S. sixth-generation fighter is still in the initial design phase. Next, the U.S. sixth-generation fighter will need at least 10-15 years to go through the processes of design, production, test flights, and mass production. This means that the hope for the U.S. to put the sixth-generation fighter into service by 2030 is very slim. At the end of 2022, the U.S. sixth-generation fighter project had not yet passed the "B stage" review process.

Meanwhile, both the northern and southern sixth-generation fighters in China have already completed their maiden flights. It can be said that, thanks to the strong industrial capacity of China, China is currently in a state of overall leadership in the development of next-generation high-tech weapons.

Original article: https://www.toutiao.com/article/7568335492928864787/

Statement: This article represents the views of the author. Please express your attitude by clicking the [top/vote] button below.