On the morning of October 1, a major breakthrough was reported at the construction site of the Compact Advanced Stellarator Experiment (BEST) in the Future Science City of Hefei, Anhui: the first key component of the device's main body - the DUV base - was successfully installed, marking a new stage in the main construction of the project and initiating an "acceleration" in component development and engineering installation.

Fusion energy is hailed as the "ultimate energy," its principle simulates the nuclear fusion reaction inside the sun, combining light elements into heavy elements and releasing vast energy. Unlike past fusion experimental devices, BEST will demonstrate the "burning" of deuterium-tritium plasma, and is expected to achieve the world's first fusion power generation. In May this year, the project's overall assembly was officially launched, and due to the construction site resembling the "planet engine" from a science fiction movie, it has attracted widespread attention. The DUV is a core component of BEST, like a giant "vacuum insulated bottle," providing thermal insulation protection for superconducting magnets working at minus 269 degrees Celsius, allowing them to better "constrain" the plasma at hundreds of millions of degrees Celsius.

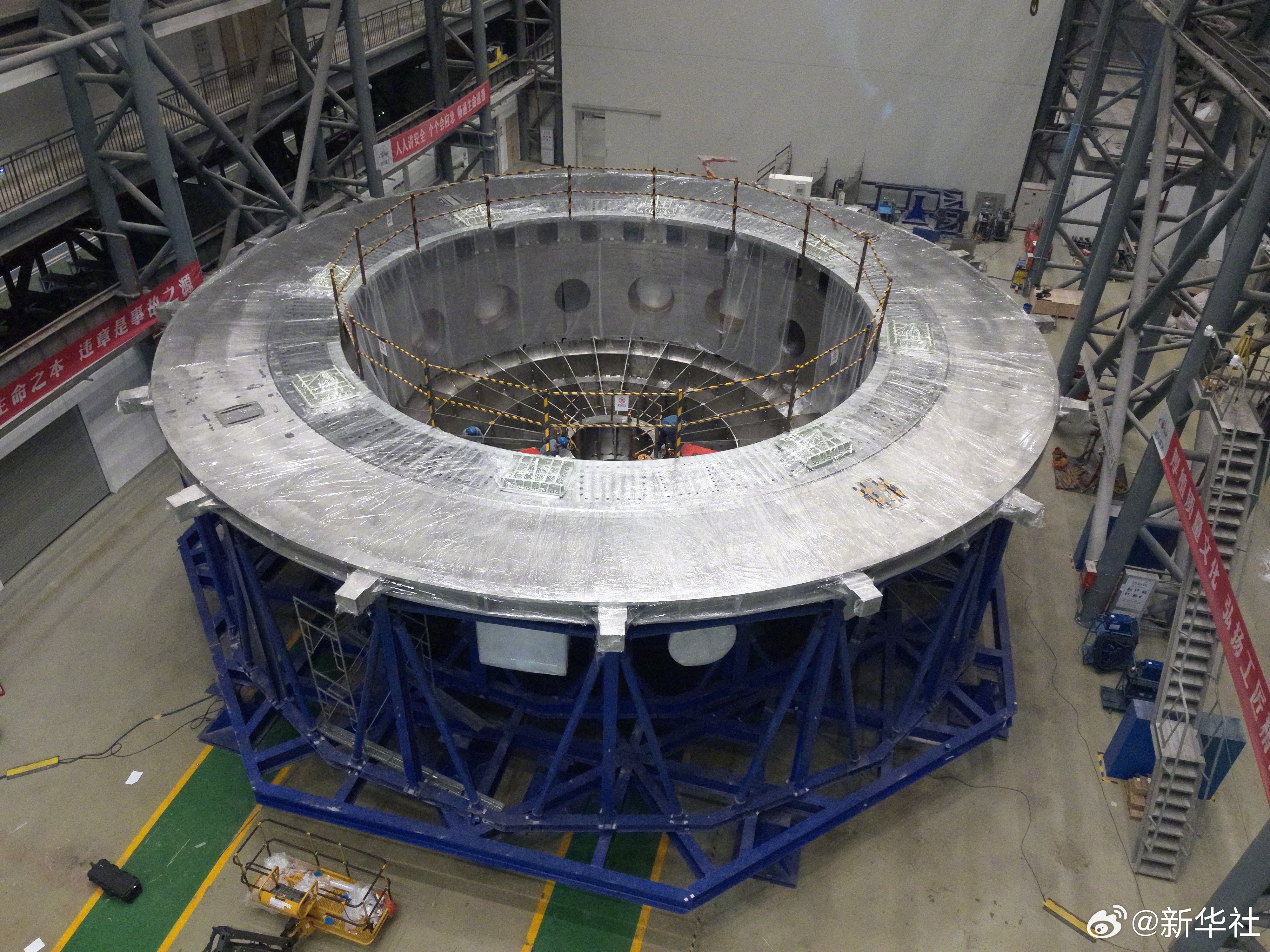

In the main hall of the BEST device, reporters saw several steel cables lifting a large "stopper"-like DUV base, slowly placing it into the central "deep pit." "The DUV base is equivalent to the foundation of the device, and will carry the weight of more than 6,000 tons of equipment in the future," said Huang Xiongyi, a deputy researcher at the Institute of Plasma Physics, Chinese Academy of Sciences, Hefei Institutes of Physical Science. This base weighs more than 400 tons, has a diameter of about 18 meters, and a height of about 5 meters. It is not only the heaviest single component in the BEST host, but also the largest vacuum component in the field of fusion in China. During the development process, the project team overcame key technologies such as high-precision forming and welding, millimeter-level deformation control, and high-vacuum sealing.

Installing such a massive structure requires extremely high precision to ensure the stability of the device in the future. The surface level difference must be controlled within 15 mm, the position deviation during placement must not exceed ±2 mm, and the gap between the base and the surrounding walls is less than 100 mm during the placement process. The project team developed a specialized hoisting system on their own and used laser tracking technology to monitor and adjust in real-time, finally achieving precise installation at the millimeter level.

According to the introduction, after the installation of the DUV base is completed, the core components of the host will be installed one by one. According to the plan, BEST will be completed by the end of 2027. The steady progress of the construction of this device has significant strategic significance for China to lead in the frontiers of fusion research, verify key technologies for future fusion reactors, and continue to lead international development in fusion energy.

(Source: Xinhua News Agency)

Original article: https://www.toutiao.com/article/7556140646520783410/

Statement: This article represents the views of the author. Please express your attitude by clicking the [Like/Dislike] buttons below.