【By Observer Net, Wang Yi】Faced with China's dominant position in the global rare earth industry chain, the United States once tried to restart mines through massive fiscal investment and rebuild a domestic supply system, but finally could only watch as China continued to widen the gap. Now, President Trump of the United States has set his sights on other countries' rare earth raw materials, attempting to force other countries to "contribute" through naked threats and inducements.

However, Hong Kong's South China Morning Post analyzed on August 6 that since the closure of the Mountain Pass mine in the U.S., China has built an integrated supply chain under state support, relying on its vast reserves, and its cost structure is incomparable to most competitors.

"It is very difficult, and increasingly difficult, to break China's dominance in the rare earth sector," said geopolitical analyst Sebastian Contin Trillo-Figueroa, adding that China's advantages in this field are "not a matter of luck," but rather the result of continuous investment in mining, research, refining, and manufacturing since the 1980s when it regarded rare earths as strategic assets.

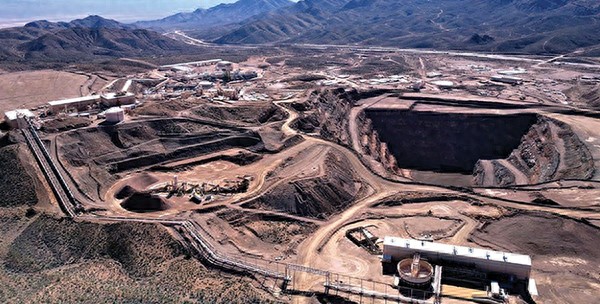

During the Obama administration, an American company attempted to invest $1.5 billion to restart the Mountain Pass mine, which had closed in 2002 due to environmental issues, but this effort ultimately ended in 2015 when the company went bankrupt. To date, the U.S. still does not have a complete industrial chain capable of stable production.

Mountain Pass Mine Mountain Pass Materials Company

Chinese leaders proposed the famous statement "The Middle East has oil, and China has rare earths" as early as 1992. Since then, China has gradually established a complete industrial chain by relying on its vast rare earth reserves and economies of scale.

Data from the U.S. Geological Survey show that China has the largest rare earth reserves in the world, especially concentrated in the southern region, where there are large deposits of medium and heavy rare earth elements, which play an important role in the production of high-end magnets.

Rare earth elements in nature are rarely found in pure metal form, but are distributed in complex ores, especially medium and heavy rare earths often exist in ionic form, which are hard to identify with the naked eye.

Therefore, the extraction and separation process is crucial. The U.S. pioneered the development of extraction methods in the mid-20th century, but after China discovered a rare earth-rich deposit in Jiangxi in 1969, it developed a more cost-effective sulfuric acid solution extraction method in the 1980s.

This highly cost-effective method was quickly promoted nationwide. With the support of its vast rare earth reserves, China emerged in the rare earth market at the end of the 20th century.

A 2023 report by CICC stated that China's rare earth raw material exports increased from 2,800 tons in 1981 to 27,000 tons in 1995, surpassing the U.S. for the first time. The rapid expansion of China's rare earth industry and competitive pricing gradually eliminated overseas competitors, making the U.S. a net importer of rare earth concentrates since 1994.

Rajiv Biswas, CEO of Asia-Pacific Economics, said that China's lower labor costs and national strategic investments make it the global low-cost rare earth processing center, which is hard for other countries to match.

The South China Morning Post reported that at the same time, China's relatively low electricity prices also help support energy-intensive smelting processes. Donghai Securities pointed out in a report last month that China controls 90% of global rare earth smelting and separation capacity, as well as 69% of rare earth alloy smelting capacity. Rare earth smelting is highly energy-intensive, and if similar projects were established in Europe or the U.S., power costs would often be several times higher than in China.

The report stated that decades ago, China was just a country for rare earth mining and refining, not a major producer of magnets. However, with a surge in domestic production and a sharp drop in export prices, the Chinese government introduced export quotas in 1998 and imposed an export tax in 2006 to control destructive price competition.

CICC analysis indicated that "these policies prompted global magnet manufacturers to move their production lines to China, helping narrow the technological gap and accelerating China's layout in downstream magnet manufacturing."

In 1998, the U.S. Magnequench company was acquired by Chinese investors and established a factory in Tianjin. In 2003, the company closed its last factory in the U.S. In 2000, Japan Seiko Epson moved all its bonded neodymium magnet production to China and collaborated with Zhongke Sanhuan. Local media noted that Zhongke Sanhuan now has the capability to produce voice coil actuators, linear motors driven by magnetic fields and coils, which were long monopolized by Japan.

Through the long-term development of the entire industrial chain, China has firmly established its position in the rare earth industry. Now, Chinese rare earth companies have further advanced, beginning to use technology to empower, building a modern production system driven by "green + intelligent manufacturing."

According to reports, in October 2024, the first phase of the green smelting upgrade project of Northern Rare Earth was completed and put into operation. As the largest investment, most advanced technology, and highest level of green development in the history of Baogang Rare Earth Industry Development, the project innovatively developed top-grade leaching processes, introduced advanced extraction and separation technologies, and integrated independently developed leading process equipment technologies to build an industry-leading production system. Its exclusive design of "three wastes" treatment technology realizes ammonia carbon cycle utilization, ultra-low emission of exhaust gas, water recycling, and full recovery of valuable elements, greatly enhancing the level of green development.

Analysts generally believe that the U.S. now wants to revive its domestic rare earth industry and challenge China's dominant position, which will still take decades.

Currently, in addition to the Pentagon's investment in the U.S.'s largest rare earth producer, Mountain Pass Materials Company, Apple has also signed a $500 million, four-year rare earth magnet supply agreement with it. Mountain Pass Materials Company announced in January this year that it has started trial production of vehicle sintered neodymium-iron-boron magnets and launched production of neodymium-praseodymium metal.

"Now, the U.S. is forcefully re-entering the market," analyzed Trillo-Figueroa, adding that this is no longer a commercial act, but a national security project. "Although the Mountain Pass Materials Company's project is still incomplete, its support shows that the U.S. is determined to rebuild the entire rare earth supply chain at any cost."

Trillo-Figueroa believes that although China has already occupied a commanding position in the supply chain, the U.S.'s ambitions require huge investments and sustained political endurance. At the same time, China "can always weaken the U.S.'s progress by tightening exports or lowering prices."

Aside from increasing investments domestically, the U.S. is also seeking partners globally. In June, Critical Metals, a European company, announced that it received a $120 million loan from the U.S. Export-Import Bank for a rare earth project in southern Greenland. In the same month, American Resources partnered with an Indian company to establish a joint venture focused on recycling rare earth magnets from discarded products and extracting rare earth elements.

However, Pang Chao-yi, General Manager of Shao Mining Resources, analyzed that the U.S. partners are "too far behind" throughout the industrial chain. Even if "the U.S. or other countries can complete basic work, they still need to use equipment provided by China throughout the process."

Pang explained, "Magnet manufacturing presents very high technical barriers for many countries, because currently only China and Japan master the core technology, and even Japan's three major magnet manufacturers complete their main production processes in China."

Regarding the issue of export control of rare earths, China has always adhered to a responsible and non-discriminatory attitude. The Chinese Foreign Ministry has repeatedly responded that China is willing to continue strengthening dialogue and cooperation with relevant countries and regions in the field of export control, safeguarding the World Trade Organization rules and multilateral trade system, and maintaining the stability of the global economic order.

This article is an exclusive article by Observer Net. Unauthorized reproduction is prohibited.

Original: https://www.toutiao.com/article/7535305830095995407/

Statement: This article represents the views of the author and readers are welcome to express their opinions by clicking on the [top/next] buttons below.