【By Observer Net, Qi Qian】According to Xinhua News Agency, on July 10, the largest U.S. rare earth producer, MP Materials, announced that the Pentagon has agreed to purchase $400 million in preferred shares convertible into common stock, making it its largest shareholder.

The U.S. government aims to promote domestic companies to explore minerals and quickly start production, breaking through key mineral bottlenecks and competing with China.

However, several industry insiders in the U.S. on July 25 said that this model may be difficult to replicate. The U.S. has rare earth resources but lacks investors willing to take risks in this industry dominated by China. They pointed out that for capital, entering mining operations recklessly carries inherent risks.

In recent years, the U.S. has been caught in a dilemma in the field of critical minerals: Washington tries to stimulate the market by investing hundreds of millions of dollars in new mines and processing plants, but establishing a domestic rare earth industry still faces difficulties due to limited private capital. Analysts say that while the White House is committed to reducing reliance on China's critical minerals, this reality exposes the U.S.'s weaknesses.

It is reported that this paradox is common among small companies trying to extract rare earth elements. Stocks of related U.S. companies are often traded on smaller exchanges in Canada or Australia, and major banks are cautious about projects that may take ten years or more to become profitable.

According to reports, in January this year, the Australian Stock Exchange-listed company American Rare Earths announced that its U.S. subsidiary, Wyoming Rare Earths, has received permission to trial the "Cowboy State Mine" project at the Hog Lake Creek site.

Yet, American Rare Earths is a penny stock.

"Financing is a big issue," said Joe Evers, president of the Wyoming project at the company. In his view, due to China's dominant position in the rare earth sector, the U.S. rare earth market "has almost no development."

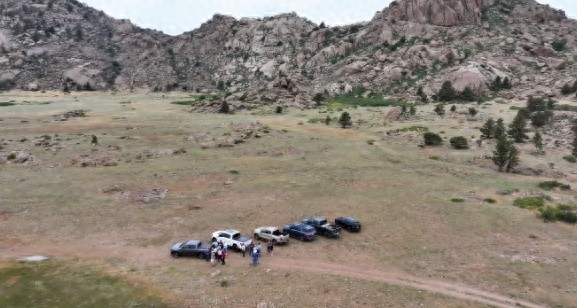

The "Cowboy State Mine" planned by American Rare Earths

Reports state that commodities like oil have mature financial markets, where companies and traders can hedge against volatility, and prices help investors assess company value and banks design loans. But the rare earth market is not like that. Although the 17 rare earth elements are needed in small quantities in high-tech industries, they are crucial.

According to data from the International Energy Agency, in 2023, China accounted for over 60% of global rare earth mine production, but its control over the processing stage accounted for 92% of global production, giving it near-monopoly control over the global rare earth processing sector. The U.S. Geological Survey also stated that between 2020 and 2023, 70% of the rare earth compounds and metals imported by the U.S. came from China.

Earlier this year, China implemented export controls on rare earths, prompting American companies like Ford to rush to find suppliers. The U.S. believes this move has increased China's leverage in the Sino-U.S. trade game. Although China has eased some restrictions, data shows that in June, China exported 3,188 tons of rare earth magnets globally, which is still a 38.1% decrease compared to the same period in 2024.

MP Materials' rare earth mining and processing facility in California's Mountain Pass

To reduce dependence on China, on July 10, the U.S. Department of Defense spent $400 million to buy shares, becoming the largest shareholder of MP Materials, the largest U.S. rare earth producer. According to an introduction, MP Materials is the only U.S. producer that has mastered the entire rare earth supply chain, as well as the only large-scale mining and processing rare earth enterprise in North America. The company owns the second-largest rare earth mine in the world, Mountain Pass, in California.

These measures have triggered dramatic fluctuations in the stock prices of similar companies, which now begin to use the slogan of "Made in America" to compete for government funding. U.S. miners hope the federal government will inspire investor enthusiasm.

American Rare Earths' stock price nearly doubled within a week, reaching 46 Australian cents per share. The company's planned "Cowboy State Mine" is expected to accelerate the licensing process. This mine contains the four core rare earth elements required for manufacturing powerful permanent magnets: neodymium, praseodymium, dysprosium, and terbium. However, the company's CEO recently resigned, marking the second leadership change since last year.

"The government has realized that this game doesn't work," said Randall Atkins, CEO of Ramaco Resources, a Kentucky coal producer. The company recently opened a coal and rare earth mine in Wyoming.

Analysts believe that relying on government aid carries risks because the U.S. policy on critical minerals has long been inconsistent. For example, the Biden administration's Inflation Reduction Act included domestic production tax credits, but the Trump administration announced that these credits would end in 2030.

Milo McBride, a researcher at the Carnegie Endowment for International Peace, said that the U.S. government's reduction of other credits for electric vehicle purchases and renewable energy development "carries the risk of stifling demand signals, unable to ensure that these emerging industries (mostly startups) have a market."

Whether the transaction with MP Materials can be replicated by other rare earth miners remains unclear to the Pentagon.

Analysts have warned that entering the mining business recklessly carries inherent risks, and certain projects are speculative. Previously, a cobalt mine in Idaho took thirty years to develop, despite receiving millions in government support, and remained stalled for years. Rod Egert, a professor of economics at Colorado School of Mines, said, "For these projects, commercial production may be unlikely, but that's the nature of the industry."

Notably, since China introduced new regulations on rare earth controls, the U.S., Australia, India, and several Western companies have accelerated their investments in critical minerals, attempting to diversify the rare earth supply chain. However, analysts point out that China has accumulated many years of expertise in rare earth processing capabilities and talent reserves, making the cost of catching up high, and other countries find it hard to easily "end" China's leading position.

Cameron Johnson, a senior partner at TidalWave, a Shanghai-based consulting firm and former vice president of the Shanghai American Chamber of Commerce, expects that other countries' strategies for diversifying rare earth supplies will face numerous challenges, including time, cost, and human capital.

"Just the time alone will take at least 10 to 20 years, and the cost will be in the tens of billions of dollars," Johnson said. "And where will the talent come from? Who knows how to process these materials? Who understands the purification process? How to achieve high purity? These talents do not exist in most countries."

This article is exclusive to Observer Net. Unauthorized reproduction is prohibited.

Original: https://www.toutiao.com/article/7531406730744431104/

Statement: The article represents the views of the author and readers are welcome to express their opinions by clicking on the 【top/down】 buttons below.