On July 26, at the World Artificial Intelligence Conference (WAIC), NetEase Lingdong, a smart construction machinery brand under NetEase, held an outdoor mine embodied intelligence technology launch event, officially introducing the world's first embodied intelligence model specifically designed for the loading scene of open-pit mine excavators — "Lingjue". This release deeply responds to the strategic goal of the National Energy Administration to achieve intelligent continuous operations and unmanned transportation in large open-pit coal mines by 2025, providing a scalable technical model for the "Guidelines for Intelligent Coal Mines".

At the NetEase Lingdong booth, visitors experienced in real-time the unmanned excavator automatic loading function from a mine in Inner Mongolia thousands of miles away through the smart cockpit. "I didn't expect AI could help us do dangerous work!" Visitors marveled at the smooth unmanned operation of the excavator.

Technological Innovation Drives Industrial Upgrading

"Lingjue", as the world's first "end-to-end" embodied model for construction machinery, completely overturns the traditional development model by relying on multimodal data-driven self-learning technology.

NetEase Lingdong technical director explained three major breakthroughs:

1. Technological Path Innovation: Abandoning the traditional modular development and scenario customization model, it pioneers an end-to-end integrated model, achieving a qualitative leap in generalization performance;

2. Data "Flywheel" Drive: Training data directly comes from real mine operation scenarios, accurately solving scene problems that simulation data cannot address;

3. Comprehensive Domestication: Built based on self-developed domestic frameworks, core algorithms and hardware chips are fully controllable, ensuring technological security and supply chain stability.

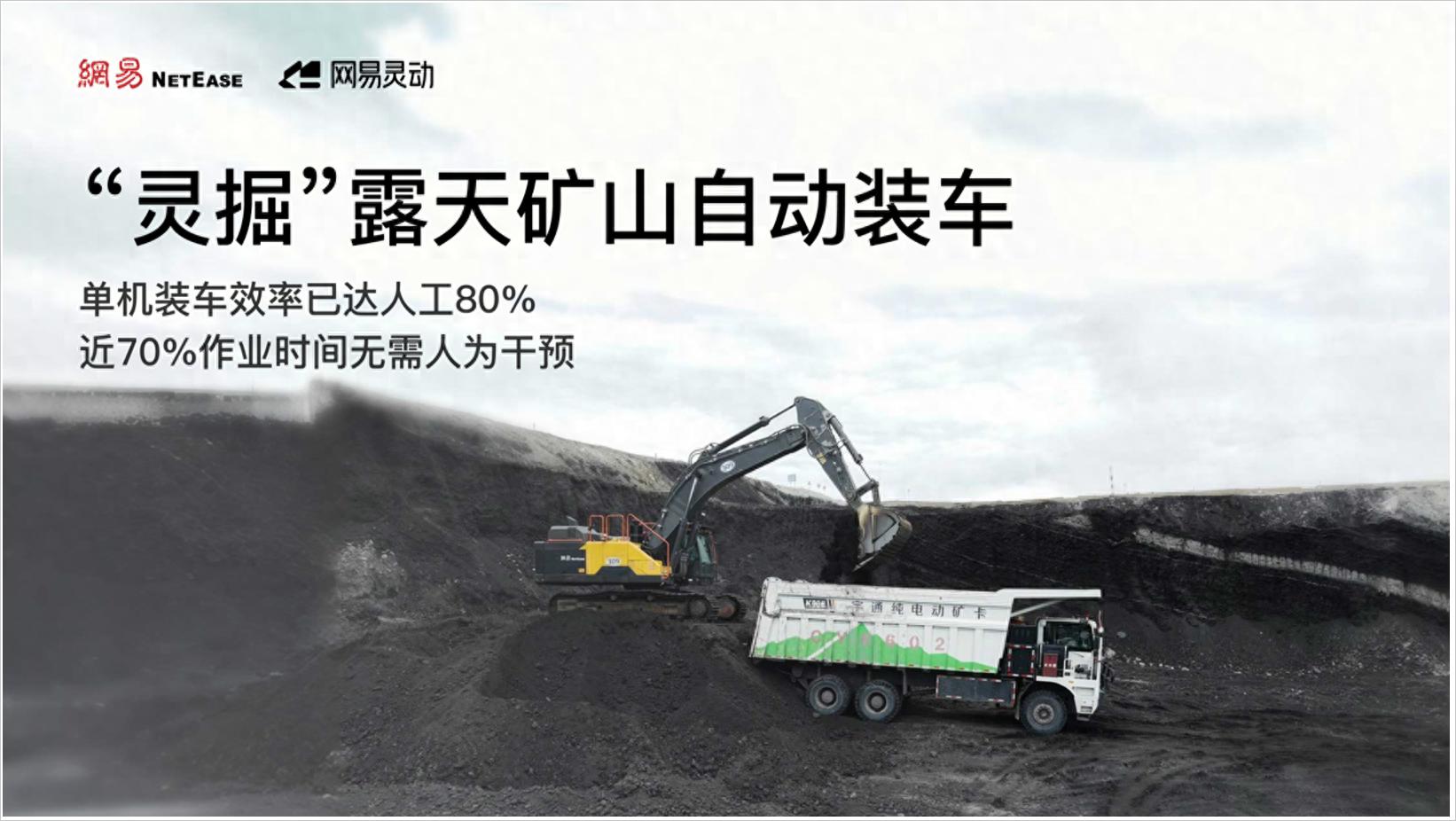

In the harsh environment of the Hohhot Open-pit Coal Mine in Inner Mongolia, the single-machine loading efficiency of "Lingjue" has reached 80% of manual operations, and nearly 70% of operating time does not require human intervention, successfully adapting to extreme cold, high dust, and other harsh environments and multiple types of mining trucks. "This technology makes AI become the 'iron-arm comrade' of the mine, with loading precision and continuity far exceeding expectations, opening up a new path for industry safety and efficiency," said a representative of an open-pit coal mine in Inner Mongolia after testing.

Building an Industrial Collaboration Ecosystem

To accelerate the popularization of the technology, NetEase Lingdong announced two initiatives: the first open-sourcing of the "Lingjue" dataset, and launching the "2027 Industrial Collaboration Plan" to the entire industry. The plan will collaborate with main machine manufacturers such as XCMG, Sany, and Shanshi Intelligent, as well as various open-pit coal mine enterprises, through a technology sharing platform to promote joint R&D, scenario co-creation, and standard formulation, aiming to achieve over 30 mines operating without people by 2027, accelerating the popularization of the technology through ecological collaboration.

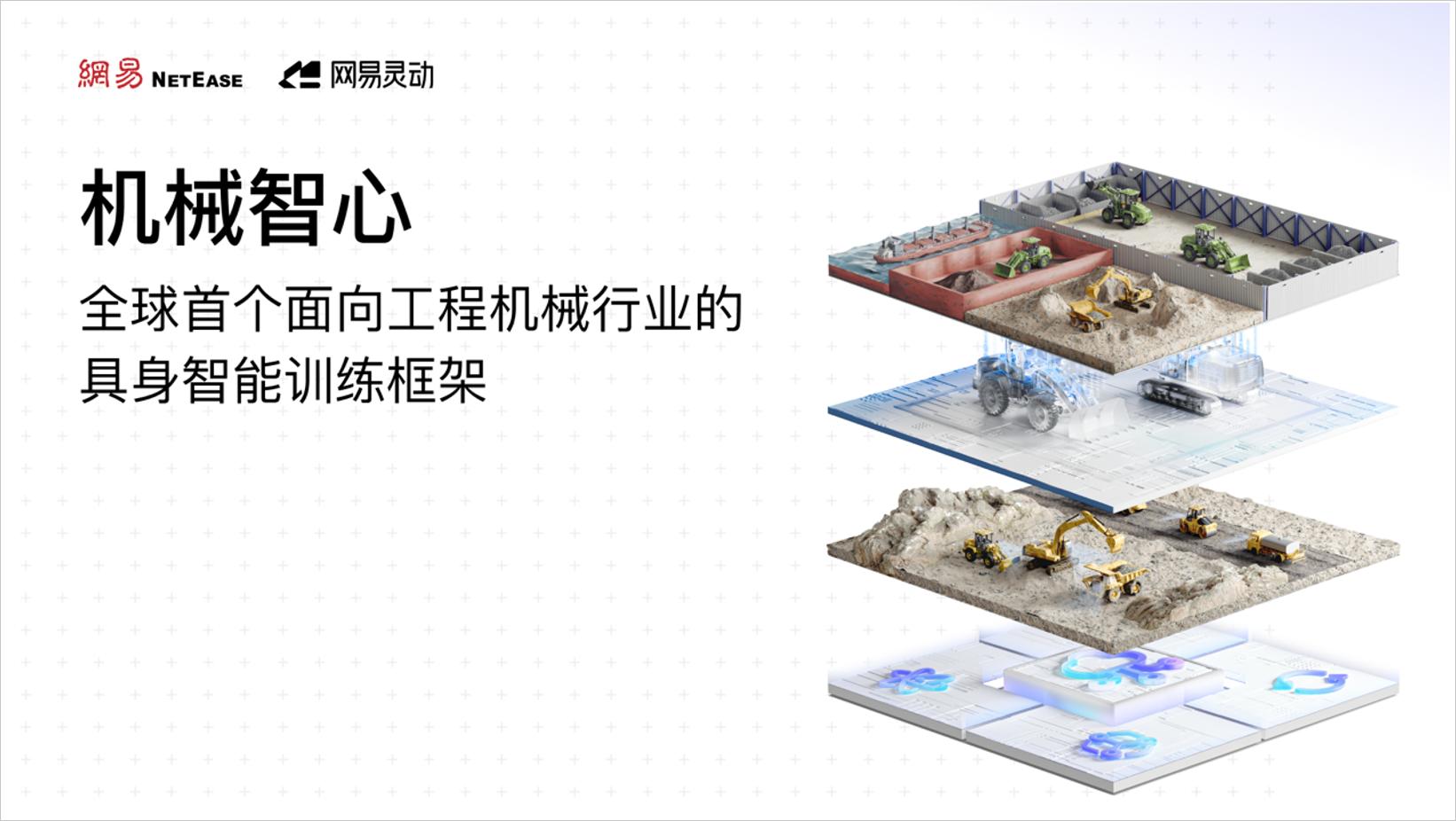

Expanding Smart Boundaries with Self-Developed Frameworks

The end-to-end training framework "Jixie Zhixin" — the technical cornerstone of "Lingjue" — uniquely integrates video learning, expert demonstrations, and reinforcement learning in three stages, granting machines dynamic evolution capabilities. This framework has supported the successful practice of "Lingjue" in mine scenarios and quickly migrated to more than ten scenarios such as port cleaning, concrete mixing stations, and ground coal sales. In the future, it will extend to fields such as agriculture and intelligent manufacturing, redefining the ecological boundaries of industrial intelligent entities.

Chinese Solutions Lead the Global Intelligent Tide

Facing the dual challenges of labor shortages and safety risks, NetEase Lingdong has previously deep-cooperated with more than 30 leading enterprises such as XCMG, Shanshi Intelligent, and the China Railway Group. The release of the "Lingjue" model and "Jixie Zhixin" has propelled construction machinery into the era of full autonomous operations.

NetEase Lingdong will continue to migrate cutting-edge game AI technologies to the physical industry, injecting new quality productivity into scenarios such as mines and ports through technology openness and industrial collaboration, providing an efficient and safe Chinese model for global industrial intelligence.

Original article: https://www.toutiao.com/article/7531374672353559103/

Statement: This article represents the views of the author. Welcome to express your opinion by clicking on the [Up/Down] buttons below.