【Text by Observer Net, Xiong Chaoran】In the future, could rocket and satellite production be as efficient as car manufacturing? Have you ever imagined that? Currently, China's aerospace industry is undergoing a quiet yet potentially transformative manufacturing revolution.

According to a report from Hong Kong's South China Morning Post on September 28, after a difficult structural reform, China's state-owned space sector is introducing a new space manufacturing model called "assembly-driven," which was inspired by the lean production principles of the automotive industry. The goal of this new system is not only to achieve rapid mass production of space systems but also to ensure stable quality, lower costs, and greater flexibility.

"This represents a systematic and disruptive transformation of the existing manufacturing model," wrote Academician Wang Guoqing, Chief Information Officer (CIO) of China Aerospace Science and Technology Corporation and a space manufacturing expert, along with his team in a paper published in the Journal of Mechanical Engineering in July this year.

Researchers point out that as new technologies drive exponential growth in global space activities, it is expected that by 2045, orbital launches will reach an effective payload of 170,000 tons per year. Countries that can master scalable space manufacturing will dominate the future.

On September 27, 2025 at 20:40, China successfully launched the 11th group of low-orbit satellites for the satellite internet in the Taiyuan Satellite Launch Center using the Long March 6A launch vehicle. The satellites smoothly entered the designated orbit, and the launch mission was a complete success. This mission marked the 597th flight of the Long March series of launch vehicles. Visual China

For a long time, spacecraft were mostly handcrafted precision masterpieces, each rocket or satellite being a unique engineering product. However, with the surge in demand for satellite constellations, reusable launch vehicles, and sustained lunar missions, traditional methods are no longer sufficient.

The paper introduces that China's space manufacturing has gone through stages of research and development-led production, and the parallel development of research and mass production, and is now entering a stage of regular high-density launches leading to large-scale customization. It is urgent to explore a manufacturing model that meets national major strategic needs and conforms to the characteristics of China's aerospace industry.

In the past, under the traditional R&D model, the assembly manufacturing unit was only the final link in the entire chain, responsible for assembly work according to the assembly plan issued by the department. It had no external constraints, and the delivery time of supporting parts did not match the assembly rhythm, causing inventory accumulation and high manufacturing costs.

The new "assembly-driven" model overturns this logic, where components are not pushed to the production line in advance, but are obtained from upstream suppliers only when needed in the final assembly, and strictly controlled in quantity.

The South China Morning Post reported that Toyota, a Japanese automaker, pioneered this famous "pull-based" production model in the mid-20th century.

By using tools such as kanban cards, each workstation only "pulls" components from the previous process when needed, thereby minimizing waste, reducing inventory, and improving efficiency. This method became the foundation of global lean production.

March 22, 2019, Tianjin Development Zone, Toyota's first overseas TNGA "new factory". Visual China

Now, China's aerospace industry has applied this just-in-time, demand-driven logic to the production of rockets and satellites. Each link, from final assembly to subsystem assembly, from components to raw materials, is triggered only when the downstream demands it.

This forms a tightly responsive flexible supply chain, where each rocket engine, solar panel, and circuit board is produced in sync with the launch schedule. This means that China's relatively flat organizational structure in the aerospace industry—granting more bargaining power and resources to suppliers—will be replaced by a pyramidal hierarchical structure.

Wang Guoqing's team pointed out that China's space program, like its global counterparts, has shifted from the early exploratory phase of "can we build it?" to achieving small-batch, reliable mass production while balancing multiple models.

They said that the world today has entered a "mass customization era," where high-frequency launches and vast satellite networks require scalable, repeatable, and flexible manufacturing methods.

In their paper, the Chinese research team mentioned that China is not the only country pursuing this goal. For example, SpaceX's Starlink project aims to build a satellite network consisting of about 42,000 satellites, and currently has launched over 7,000, demonstrating remarkable satellite mass production capabilities.

However, unlike the U.S., which is dominated by a single company, China's development path appears more networked and driven by an ecosystem, relying on the collaboration of state-owned enterprises, research institutions, and private suppliers to form a national strategy.

The construction of China's low-Earth-orbit satellite internet constellations, such as the National Grid Constellation, Qianfan Constellation, and Honghu No. 3 Constellation, has entered a dense networking phase, urgently requiring the scalability of satellite and launch vehicle production. In the coming years, China will produce thousands of product devices.

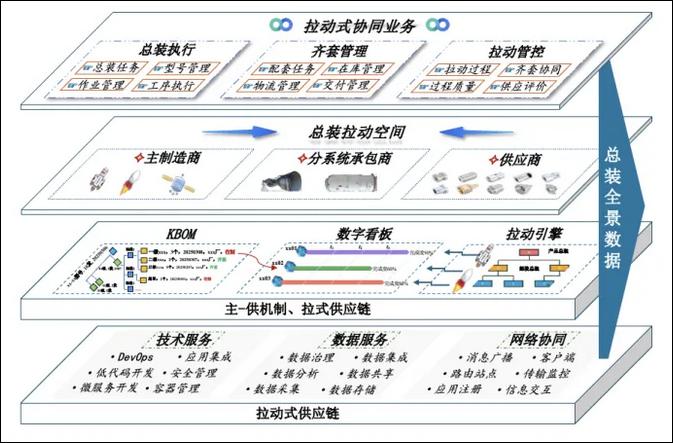

Wang Guoqing's team believes that the proposal of the "assembly-driven" manufacturing model will provide important support for completing major space missions and upgrading the space manufacturing industry. They also believe that this transformation requires a "comprehensive spirit of self-reform," and in the paper, they provided more details on how "assembly-driven" works.

The overall manufacturing unit assumes the management responsibility for organizing and implementing large-scale customized production tasks, bearing five management responsibilities: contract funding, planning coordination, quality assurance, capability building, and supply chain control.

Building modular, flexible, networked, and intelligent manufacturing capabilities with the standards of high efficiency, high quality, and high elasticity. Planning the production rhythm based on capacity, by arranging modular workstations, optimizing operation processes, and balancing workstation working times, taking the assembly rhythm as the source of the entire chain pull production, adopting a pulsating production mode to reshape the assembly manufacturing capability.

The intelligent flexible assembly center uses artificial intelligence and robot technology to dynamically reconfigure the workflow of different types of rockets, making it suitable for mixed production of various launch vehicles.

Another breakthrough is the collaborative manufacturing platform, which connects factories, laboratories, and suppliers across the country, even crossing different confidential networks. The platform uses cloud computing, the Internet of Things, artificial intelligence, and digital twins to realize real-time tracking of production status, immediate visualization of supply chain bottlenecks, automatic warnings for missing parts, and secure data sharing across institutions.

A system called "Digital Kanban" allows managers to monitor the entire supply chain in real time.

Architecture diagram of the collaborative manufacturing platform, screenshot from the paper

The South China Morning Post concluded that this reform coincides with the acceleration of China's space launches. In 2024, the United States completed 158 orbital launches, mostly executed by SpaceX; while China completed 68 launches, setting a new record compared to 67 launches in 2023, but there is still a significant gap compared to the "around 100 launches throughout the year" predicted in the 2023 China Aerospace Science and Technology Activity Blue Book at the beginning of 2024.

Observer Net columnist and aerospace media writer of "Aviation Words" Gao Tianwei stated that in 2024, China maintained a steady performance in traditional aerospace areas, especially in key national projects, but there was a significant deviation between reality and plans in the emerging commercial aerospace field.

Although China's emerging commercial aerospace companies faced some challenges in 2024, looking at the industry's ten-year evolution and the development trends of foreign peers, society has already recognized that emerging commercial aerospace companies can flexibly and efficiently exploit technological resources to provide more diverse aerospace services, and should continue to be supported and developed.

This article is exclusive to Observer Net. Unauthorized reproduction is prohibited.

Original text: https://www.toutiao.com/article/7555419870104420914/

Statement: This article represents the views of the author. Please express your opinion by clicking on the [top/vote] buttons below.