【By Observer Net, Qi Qian】

The U.S. military is investing heavily to reduce its reliance on Chinese drones.

According to a November 10 report by the New York Times, although specific financial terms have not been disclosed, the Trump administration plans to allocate over $36 million in 2026 for drone procurement. U.S. Army Secretary Daniel Criswell recently stated that the Army plans to purchase at least 1 million drones within the next two to three years. Although government shutdowns have affected military procurement, some existing contracts continue to move forward.

In recent times, a little-known company called Neros has been selected as one of the three American manufacturers for the first phase of the U.S. Army's "Purpose-Built Attritable Systems" (PBAS) program, supplying low-cost, disposable Archer drones to the Army.

This company was established less than two years ago, and its two bosses are 22-year-old Soren Monroe-Anderson and 24-year-old Olav Sihvaa.

The report states that during their teenage years, they relied on components such as propellers, motors, and batteries supplied from Shenzhen to participate in competitions; but now, how to build a supply chain without Chinese components while keeping costs under control has become their biggest challenge. In addition, the company only manually assembles about 2,000 drones per month, far behind the production levels of Chinese companies that reach millions.

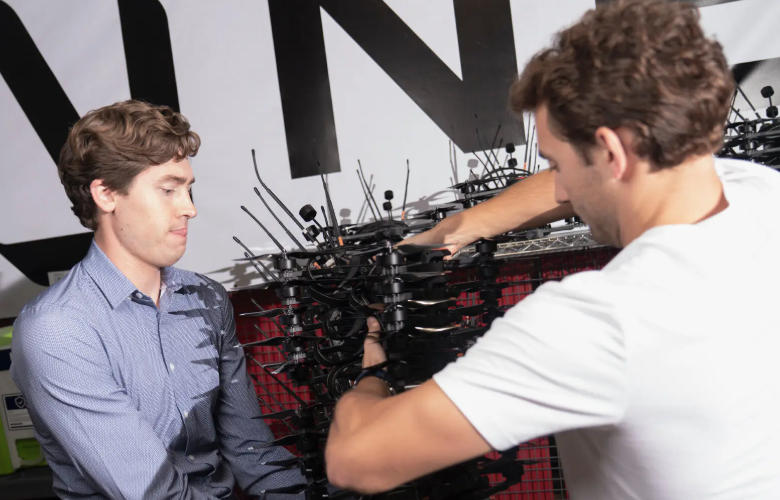

Two founders demonstrating the Archer drone, U.S. media

The report states that Neros' selection comes at a time when the U.S. military is urgently seeking to address competitive pressures in the drone field.

It is known that Monroe-Anderson and Sihvaa founded the drone company Neros in 2023, quickly gaining recognition in the defense sector with its flagship product, the Archer drone. The company is based in El Segundo, California, with approximately 80 employees, most of whom are older than the founders. Its Chief Operating Officer, Sean Wood, worked at SpaceX for 12 years.

Recently, the company completed a $75 million funding round led by Sequoia Capital, bringing total funding to $121 million, and secured a $17 million contract with the Marine Corps to supply thousands of drones. The company also supplies 6,000 drones to Ukraine.

Their expertise in drones stems from their experience in drone competitions during their teenage years. According to them, the inspiration for Neros came from the 2022 Ukraine-Russia conflict, where Ukraine used simple modified quadcopters to repel Russian forces.

The Archer drone from Neros company

This summer, during a test flight in Alaska, Monroe-Anderson's Archer successfully resisted interference devices, attracting military attention.

In July, when the U.S. "Secretary of War" Hagel announced policy adjustments to accelerate domestic drone production, the Archer was on display. Major Steven Atkinson of the Marine Corps' combat laboratory said in May that it was difficult to find U.S. small drone suppliers with prices below $2,000, until they discovered Neros, "their achievements are unprecedented."

The Archer is an 8-inch (approximately 20 cm) quadcopter, weighing between 0.9 to 1.4 kg, capable of carrying a payload of about 2 kg, with a range exceeding 20 km, able to fly day and night and in adverse weather conditions, equipped with broadband video transmitters and multi-frequency controls to enhance anti-jamming capabilities. The drone is reportedly free of Chinese components, ensuring supply chain security, with a unit price of around $2,000, significantly lower than traditional military drones.

Neros has also developed the Flatbow ground control system, providing soldiers with a mobile control platform resistant to electromagnetic interference.

However, the Archer drone emphasizes speed and agility, requiring five days of training for soldiers to operate, whereas commercial drones produced by DJI do not require special training to fly, and DJI holds more than 75% of the global commercial drone market.

The report points out that Neros' rapid rise is due to the experience from the Ukrainian battlefield and support from the Pentagon, but to achieve targets of 10,000 per month, even a million per year, they need to overcome production scale and supply chain bottlenecks.

Monroe-Anderson and Sihvaa also admitted that the biggest challenge they face is building a supply chain without Chinese components.

They mentioned that during their teenage years, they relied on components supplied from Shenzhen for their drone competitions; but now, to meet military requirements, they need to build a supply chain in the United States.

"American suppliers would laugh at us," Sihvaa revealed. Once he wanted to buy a radio made in the U.S. priced at $30, but when he compared prices, he found that the price of a U.S.-made radio could be as high as $10,000. He said this made him realize quickly that they had to manufacture parts themselves and seek suppliers outside the defense industry.

Sihvaa gave an example, stating that Neros did not use computer chips commonly found in military equipment, which cost hundreds of dollars each, but instead used a chip designed for parking meters, costing just $1 per piece.

But for Neros, mass production remains a challenge. Last year, Sihvaa went to Shenzhen to meet Chinese suppliers who had supplied his drone components when he was in his teens, and these suppliers can produce over a thousand drones per day.

Sihvaa said that when he visited the factories of Chinese companies, he tried to remember as much as possible about the machines they used, and was shocked by the gap between Chinese enterprises and Neros. "We can barely assemble 2,000 drones per month, while they can do it in two days."

This article is exclusive to Observer Net. Unauthorized reproduction is prohibited.

Original: https://www.toutiao.com/article/7571310772471546368/

Statement: This article represents the views of the author. Please express your opinion by clicking on the 【top/down】 buttons below.